微孔密纹网

席型网学名密纹网,是采用优质不锈钢丝编织而成。主要特点是经向、纬向丝径和密度有较大反差,因而网子厚度和过滤精度及使用寿命比方孔网有较明显的提高,它的过滤精度是方孔网无法实现的。相对于方孔网适合作为筛网用于固体的筛分,席型网适合用作过滤网应用于液体过滤领域。

常用目数过滤网的过滤精度:

1800目(过滤精度10um),2000目(过滤精度8um),2300目(过滤精度5um),2800目(过滤精度3um),3000目(过滤精度2um),3200目(过滤精度1um),3500目(过滤精度1um)。

|

|

|

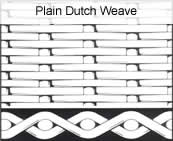

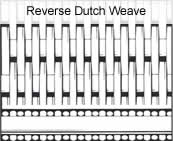

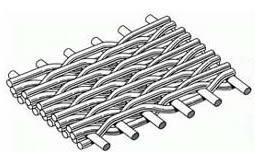

| 平纹密纹网 | 斜纹密纹网 | 反向密纹网 |

特点:

- 平纹密纹网:易清洗,低流阻,但强度低。

- 斜纹密纹网:表面光滑,但流阻较高。

- 反向密纹网:高强度,低流阻,高纳污量。

规格:

- 材质:不锈钢丝编织网使用SUS302、304、316、304L、316L不锈钢丝的编制而成。

- 编织方式:平纹密纹,斜纹密纹,反向密纹。

- 目数:40–1970#席型网(金属丝编织密纹网)

平纹密纹网

| 规格滤网号 | 经纬丝根数(/25.4mm) | 金属丝直径(mm) | 单位面积网重(kg/m2) | ||

| 经丝 | 纬丝 | 经丝 | 纬丝 | ||

| PM28 | 7.1 | 40 | 0.71 | 0.63 | 5.26 |

| PM33 | 8.4 | 75 | 0.5 | 0.355 | 2.99 |

| PM40 | 10.2 | 75 | 3.11 | ||

| PM45 | 11.4 | 75 | 3.19 | ||

| PM50 | 12.7 | 75 | 0.45 | 3.11 | |

| PM55 | 14 | 75 | 3.18 | ||

| PM60 | 15.2 | 100 | 0.4 | 0.28 | 2.57 |

| PM74 | 18.8 | 110 | 0.355 | 0.25 | 2.34 |

| PM80 | 20.3 | 110 | 2.39 | ||

| PM90 | 22.9 | 120 | 0.315 | 0.224 | 2.14 |

| PM100 | 25.4 | 140 | 0.28 | 0.2 | 1.9 |

| PM110 | 27.9 | 150 | 0.18 | 1.82 | |

| PM120 | 30.5 | 150 | 0.25 | 1.74 | |

| PM140 | 35.6 | 200 | 0.244 | 0.14 | 1.43 |

| PM160 | 40.6 | 220 | 0.18 | 0.125 | 1.21 |

| PM180 | 45.7 | 250 | 0.16 | 0.112 | 1.08 |

| PM200 | 50.8 | 280 | 0.14 | 0.1 | 0.95 |

| PM220 | 55.9 | 280 | 0.97 | ||

| PM240 | 61 | 300 | 0.09 | 0.93 | |

| PM260 | 66 | 300 | 0.125 | 0.89 | |

| PM280 | 71.7 | 350 | 0.112 | 0.08 | 0.78 |

斜纹密纹网

| 规格滤网号 | 经纬丝根数(/25.4mm) | 金属丝直径(mm) | 单位面积网重(kg/m2) | ||

| 经丝 | 纬丝 | 经丝 | 纬丝 | ||

| XM80I | 20 | 260 | 0.25 | 0.2 | 3.14 |

| XM80II | 20 | 200 | 0.355 | 0.28 | 4.58 |

| XM80III | 20 | 150 | 0.45 | 0.355 | 6.02 |

| XM95 | 24 | 300 | 0.28 | 0.18 | 3.01 |

| XM120I | 30 | 340 | 0.16 | 2.84 | |

| XM120II | 30 | 250 | 0.2 | 3.41 | |

| XM160I | 40 | 560 | 0.18 | 0.1 | 1.73 |

| XM160II | 40 | 430 | 0.125 | 2.09 | |

| XM200I | 50 | 600 | 0.125 | 0.09 | 1.47 |

| XM200II | 50 | 500 | 0.14 | 0.112 | 1.83 |

| XM255 | 65 | 600 | 0.09 | 1.59 | |

| XM275 | 70 | 600 | 1.61 | ||

| XM320 | 81.3 | 780 | 0.1 | 0.08 | 1.17 |

| XM360 | 91.4 | 789 | 0.071 | 1.21 | |

| XM400I | 101.6 | 900 | 0.063 | 1.13 | |

| XM400II | 101.6 | 780 | 0.071 | 1.24 | |

| XM500 | 127 | 1100 | 0.071 | 0.05 | 0.85 |

| XM520 | 132 | 1100 | 0.86 | ||

| XM630I | 160 | 1500 | 0.063 | 0.036 | 0.67 |

| XM630II | 160 | 1400 | 0.04 | 0.72 | |

| XM685 | 174 | 1400 | 0.78 | ||

| XM795 | 202 | 1800 | 0.05 | 0.032 | 0.57 |

| XM850 | 216 | 1900 | 0.045 | 0.03 | 0.52 |

| XM1000 | 254 | 2000 | 0.04 | 0.028 | 0.5 |

| XM1250 | 325 | 2300 | 0.036 | 0.025 | 0.44 |

| XM1280 | 400 | 2800 | 0.03 | 0.018 | 0.36 |

| XM1280 | 400 | 3200 | 0.025 | 0.015 | 0.34 |

| XM1970 | 500 | 3500 | 0.025 | 0.015 | 0.30 |

反向密纹网

| 型号 | 丝经–径×纬(mm) | 过滤度(um) | 有效截面积% | 网重(kg/平米) | 目数–径×纬 |

|---|---|---|---|---|---|

| FM18 | 0.40 x 0.60 | 210-230 | 60 | 4.21 | 63 x 18 |

| FM20 | 0.24 x 0.60 | 210 | 58 | 3.38 | 107 x 20 |

| FM40 | 0.20 x 0.45 | 130 | 58 | 2.74 | 170x 40 |

| FM50 | 0.20 x 0.40 | 105 | 55 | 2.69 | 132×32 |

| FM46 | 0.15 x 0.30 | 85 | 54 | 2.05 | 171 x 46 |

| FM75 | 0.09 x 0.20 | 38-45 | 53 | 1.27 | 290×75 |

| FM102 | 0.040x 0.16 | 40-48 | 41 | 0.92 | 615×102 |

| FM130 | 0.04 x 0.13 | 18-23 | 49 | 0.85 | 625×135 |

| FM150 | 0.035 x 0.10 | 16-20 | 54 | 0.6 | 720×150 |

Stainless steel wire mesh has excellent resistance to acid, alkali, heat and wear, because of these performance, it is widely used in filtering, screening, pharmacy, chemical and food industry, etc.

Features:

- plain dutch weave wire mesh is easy to clean and has a low resistance to flow,but is of limited strength;

- dutch twilled weave wire mesh permits the advantage of a very smooth surface on both side,its disadvantage is a relatively high resistance to flow;

- reverse plain dutch weave wire mesh is the strongest filter weave in commercial production,as a result,couples with its good flow characteristic and high dirt holding capacity,it is widely used industrially.

Specifications:

Materials of Stainless Steel Wire Mesh is mainly divided into Type 304, Type 304 L, Type 316 and Type 316 L.

Weaving method:Plain Weave,Twill Weave,Dutch Plain Weave,Dutch Twill Weave,reverse plain dutch weave.

|

|

|

|